You’ve probably noticed us always mentioning about 3D printers when it comes to revolutions that came to the construction industry in the past 10 years. The first time that it was introduced to the world, we were actually amazed by how fast it can be to build a structure. It’s potential to construct skyrise buildings in just a month or two has made Dubai one of its pioneering users.

While the process seems like a game to those who’d rather go with the traditional way of constructing buildings, this revolutionary construction actually drives property sales and significant savings. And it is not just Dubai who saw this kind of opportunity that this cutting-edge building process brings.

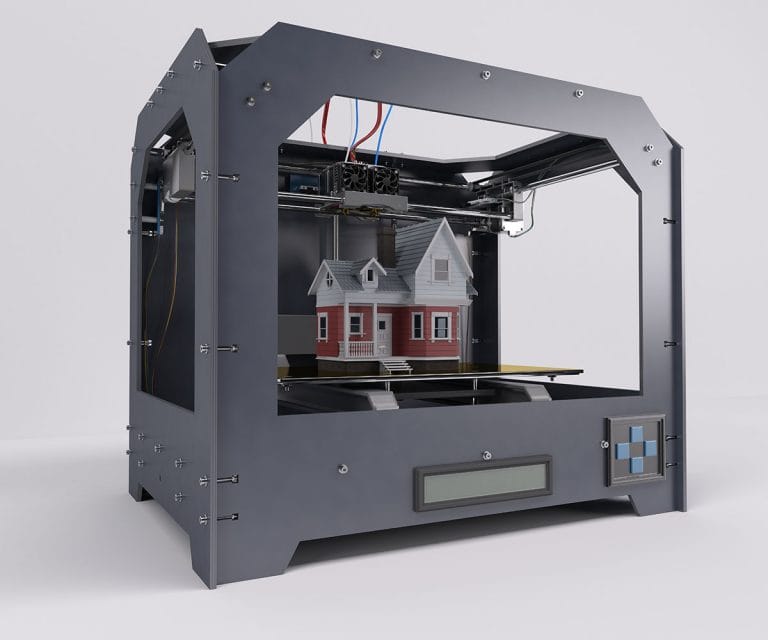

3D Printing and How it Works

Construction is such a tedious work (and dangerous too!). But with the birth of a process that can make the work faster, lighter, and probably safer, many firms have already delved into construction by 3D printing. In fact, data states that 20 commercial buildings around the world have been built using this method. And the first recorded building created using 3D printing was the COBOD International in the Danish capital of Copenhagen in 2017.

Now how this method works can be compared to a baking mixture squeezed out of a piping bag. In practice, a mixture of cement and other materials are squeezed out of a nozzle attached to a robotic arm that’s operated by a computer. The first models of 3D printers were stationary and the more modern one is now installed along rails so it can easily form a structure.

Basically, concrete is stacked layer upon layer until it produces the desired structure that you designed. It can build walls and other components like archway or void.

Dubai is an ambitious builder and we can see it with the designs and heights of the buildings it creates. Its aim to be crowned leader of high-tech construction led it to make what it claims to be the first 3D-printed office and a 3D-printed drone research laboratory in the world. Reports reveal that the 3D-printed cost only $140,000 to build.

Advocates of 3D Printing are claiming that the method can make work faster, cheaper, and more environmentally friendly than traditional building methods. They also say that there is greater flexibility in design since what you imagined in your 3D modeling software is exactly what will be printed. Furthermore, the group claims that 3D printing is used for more efficient use of materials and higher levels of sustainability by reducing waste typical of construction, and even less noise pollution.

Advantages of Using 3D Printing in Your Construction

Advances in 3D printing have allowed contractors to craft almost anything they can design on the software. It offers an innovative and competitive opportunity for firms to showcase their talent in designing modern buildings.

To mention a few more advantages, here are other good things you can enjoy from using the 3D printing construction method:

1.Reduce Material Costs

There is a considerable reduction in construction waste using a 3D printer. This equipment is known to use the exact amount of materials needed for a certain structure like floors or walls. Hence, contractors don’t need to order too much as the 3D printer and its design system will already tell you the exact quantity of material you’ll need for construction. Not only is this a more sustainable and eco-friendly way of building but a great reduction to construction cost. We suggest connecting it with your construction project management software, too, like Pro Crew Schedule, so that your cost savings can be accurately quantified.2.Reduce Injury

Since the printer does most of the work, there is now a lesser risk of injuries in the field. Considering that building with concrete is difficult and tiring (talk about cement pouring for floors), making it more dangerous to workers who are already worn out. With 3D printers, workers don’t only get an easier time doing their job but contractors are also saved from expensive compensation when a member gets badly injured.3.Reduce Construction Time

One of the biggest and most obvious benefits of using 3D printing in construction is the quicker turnaround of the project. From those who already used the technique, it has been proven that 3D printing can reduce construction time by months. Houses built in China reportedly take only a week to finish, including the installation. Some firms on heavy-duty 3D printers can even finish a single floor house in just 24 hours!As 3D printing tech goes through more improvements, it may be possible for us to see construction finished in just a few hours. Buildings may only take a month to be erected. Sooner, more contractors may shift to using the technique, most especially that there is an ongoing shortage of construction workers. This will also be beneficial for contractors who want to move onto other projects sooner.4.New Markets

We mentioned 3D printers making construction more flexible. This means contractors are able to work on complex designs that they aren’t able to accomplish using traditional construction methods. Consequently, they may be able to enter markets that were once inaccessible to them. And when they’re able to explore new markets, they can earn new competency against bigger firms that have been around for decades.On the other hand, established construction firms can consider using 3D printing to give them a new competitive edge so they can remain relevant in the market. Similarly, traditional and established construction companies could utilize 3D printers to make sure they remain relevant in the market.5.Cost-Effective Construction

Using 3D printers can fill in for several pieces of equipment like cement mixers, forklifts, cranes, etc. which are essential in making structures. Hence, it makes the operation much less costly than using several pieces of equipment. Furthermore, we’ve pointed out how 3D printing can reduce injuries on the site as well as the cost of materials needed. All these will definitely lead to a dramatic increase in profits.6.Improved Form

Tools and machines always give a better form because of the accuracy they put on their operation. 3D printers are no different. In fact, 3D printers are renowned for their ability to create seemingly odd and atypical design structures. Construction firms are now taking advantage of that feature to create unique buildings that used to be difficult to achieve using traditional methods.7.Higher Durability

The first time that 3D printers were launched, we heard about the structures being fireproof and earthquake resistant up to magnitude 8. Originators claim that they found 3D printers to contribute to the durability of the structural elements. This, they say, accounts for how the materials are made and the manner in which they are assembled just like how building block toys are difficult to break when they are tightly assembled. This means we might soon see buildings that will last a lifetime.8.Brand Improvement

With all these benefits that 3D printers bring, your firm can become the talk of the town and the new role model of younger firms. This leads to your improved brand awareness.Construction companies using traditional methods of building are thought of to be wasteful. But 3D printing is known to reduce waste so using this technique will give new light to your company as a firm that fosters sustainability. As you know, clients now prefer eco-friendly structures since green means lesser costs allotted on materials and construction. Hence, contractors that could use a little help in their branding could do well to procure and utilize a 3D printer.The challenges of concrete 3D printing

Despite the many benefits a firm can enjoy from using 3D printing, there are also challenges that come with this cutting-edge technology. People are used to traditional methods of construction. Since the public is don’t have the technical knowledge when it comes to construction, all they care about is that the building was built by experts and reliable developers. 3D printing is still new to them. Hearing that the structure was built in just a couple of days, they tend to doubt the quality immediately.

An expert described 3D printing as “emerging” but with “huge potential”. It will open the market for more cement-based construction projects. In fact, in 2016, a leading cement maker LafargeHolcim partnered with XtreeE, a French 3D-printing systems provider, in exploring how they can collaborate using the technology.

But they found out that a challenge that comes with 3D printing is related to reinforcement and further understanding of material processing and properties. The design codes of building structures also are not yet updated with the principles used in 3D printing.

Possible Impact on Construction Jobs

We mentioned earlier about 3D printers being able to do the jobs that are completed by several tasks like wall building where crew members need to drive forklifts or crane to gather the materials, operate a bricklayer if you are going to use bricks for the wall or a cement mixer for concrete. This also suggests that there are a few people needed when 3D printing is implemented.

While 3D printing gives an opportunity to bridge the growing scarcity of human labor, this technology may be just one element in the overall industrialization and digitization of the industry. Looking at the brighter side, this will lead to a shift to higher-skilled workers and newly emerging job profiles.

Overall, though, 3D printing is still a “baby” in this industry. But firms that are as ambitious as Dubai will certainly boost the quick enhancement of this technology, building design codes intended for 3D printing, and bring it closer to the mass construction market.