In the construction industry, the last impression matter. Project owners expect a seamless turnover process essential to efficient facility operations and management. For general contractors, a stress-free handover turnover process is also a way to retain loyal customers and win more work through successful referrals.

But while project closeout is essential, planning for a seamless turnover happens even before the groundbreaking begins. As a matter of fact, the process starts as early as the designing phase and is carried on throughout the project lifecycle.

The primary motivating force behind a successful project is better commissioning, applied throughout the entire construction schedule from start to finish.

What is Commissioning?

The term commissioning originated from the shipbuilding industry- a commissioned ship is considered ready for service. However, before being given this title, a ship must pass various milestones. Necessary equipment is installed and tested, issues are identified and corrected, and extensively trained the entire ship crew. Ultimately, a commissioned ship is one whose systems, materials, and crew have completed a thorough quality assurance process.

Applying the idea in the construction industry, commissioning uses the same approach to new buildings. When a newly erected building is initially commissioned, it goes through an intensive quality assurance process that starts during design and extends to construction, occupancy, and maintenance. Commissioning guarantees that the new building operates as the owner intended and that assigned building staff are prepared to operate and maintain the systems and equipment properly.

As for already existing structures, there are two types of commissioning that are implemented:

1. Retro-commissioning

This process seeks to improve how existing building systems and equipment function together. Based on the age of a structure, retro-commissioning can often resolve issues during design or construction operations or address problems that have manifested throughout the building’s life. All in all, retro-commissioning enhances an existing building’s operations and maintenance (O&M) procedures to improve overall building performance.

2. Recommissioning

Another type is referred to as recommissioning, which occurs when a building has already been commissioned undergoes the process again. The choice to recommission may be caused by a change in building ownership or usage, the onset of operational issues, or other needs. Typically, a plan for recommissioning is incorporated as part of a new building’s commissioning process or an existing building’s retro-commissioning function.

What are the Benefits of Commissioning in Construction?

Generally, the primary objective of construction commission planning is to provide direction for the entire construction process. Acting as a road map for the construction crew management, it outlines roles and responsibilities of employees and teams, includes lines of collaboration and reporting, provides a resolution process for conflict, and provides overall crew coordination.

Commissioning and recommissioning plans are intended to ensure that very complex operating systems are functioning as intended. The commissioning process helps the project owners and building managers know that their buildings’ installed systems and equipment are running correctly, smoothly, and as planned.

Project owners often have a specific set of building standards that must be met, and a commissioning process can help with that. There are numerous benefits to commissioning, including a better operation, a smoother construction process, and cost savings. Below, we will dive a little deeper at the benefits of using commissioning when you manage a project:

1. Streamlined Construction Process

Many construction projects have specific operational requirements and standards that must be met before turnover occurs. This can include confirming a lighting system or that a heating and cooling unit properly controls the temperature within a structure.

An early commissioning process can help ensure that the building operations meet these standardized requirements and help assure your building conforms to the necessary codes and laws. Additionally, early commissioning operating systems in the construction process lead to fewer warranty issues by operating managers and contractors after the turnover.

2. Better Building Operation

Commissioning can also ensure a better operation of the building system throughout its lifetime. Commissioning engineer offers an easy turnover procedure to the permanent maintenance staff. These engineers can explain to the operating staff how the system should be operated, fixed, and maintained should a problem occur.

Furthermore, commissioning the system early on assures that the installation and maintenance were done the first time correctly- good project scheduling management is the key to implementing this.

3. Cost-Efficient

The next biggest benefit of commissioning a building operating system is that it saves a lot of money. By having an operating system running correctly and with no issues, project owners are sure to save money on operation and repair costs. A system that is running correctly is a system that runs efficiently without wasting unnecessary costly utilities. Furthermore, if the system runs smoothly, it eliminates the need to replace expensive parts that deteriorate before their time. The installed equipment will remain functional and require fewer repairs and replacements as the system ages.

Lastly, owners can save money with fewer change orders arising if a project is commissioned early. Knowing how a system operates can save money by ensuring that the design is correct and efficient. Changing orders when a system is already installed and running can prove very costly, and the owners understand this.

What are the Contents of a Construction Commissioning Plan?

1. General Project Information

This section of the commissioning plan outlines the project’s basic information, such as the project name, building type, address, building description, owner name or agency, and scheduled completion date.

2. The Commissioning Scope of Work

This section of the plan documents the official equipment checklist for the building project. These systems will need to be commissioned and tested in any general construction project: HVAC system, plumbing system, electrical system, and any other systems and equipment that would be installed.

3. The Commissioning Crew Information

The plan will include information about every staff and company involved in the entire construction process. This information might consist of the owner, construction manager, mechanical engineer, commissioning provider, electrical engineer, general contractor, field architects, etc.

4. Construction Project Schedule

This section includes the conclusion of the scheduling planning for the project, from the initial design phase to the final commissioning report and turnover.

5. The Crew’s Roles and Responsibilities.

This section of the plan will outline the teams’ roles respectively and their descriptions. This can include every role listed in the Commissioning Crew Information section, followed by a description of each team’s responsibilities and how they fit into the construction project.

6. Construction Management Plan and Protocols.

Every construction project needs protocols for handling different situations since protocols ensure the operations run more smoothly. For instance, this section of the commissioning plan might include the protocol for requesting information or requesting formal documents during the construction process.

The Construction Commissioning Process

1. The “Scope of Work” Meeting

All stakeholders included in the design, management, and operations teams will come together to decide upon the scope of work required, schedules, tasks, and responsibilities before implementing the commissioning plan.

2. Finalizing the Commission Plan

The construction crew will finalize the commissioning plan draft using the details gathered from the “scope of works” meeting. The timeline is also be finalized in this step as the construction progresses.

3. Establishing Proper Documentation Control

All project design requirements for the building system and equipment must be documented to provide a baseline of performance expectations. These expectations will need to be aligned with the actual performance of the installed systems once they’re already operational.

4. Providing Submittals

The assigned commissioning professional will be provided with the system and equipment submittals by the contractor. The submittal data includes the installation and startup instructions, performance data, temperature control procedures, and more.

5. Regular Site Visit and Inspection

The professional commissioning needs to make frequent site visits to personally witness equipment and system installations to ensure that everything is running according to the commission plan.

6. Pre-functional Testing Checklists and Procedures.

Initial testing inspection checklists are provided and filled out for all mechanical and plumbing equipment being commissioned. This is to guarantee that all the systems are complete and operating.

7. Actual Execution of Testing and Commissioning (T&C)

Next, the commissioning professional will schedule functional testing through the general contractor or subcontractors. When it is scheduled to run performance tests, the commissioning professional will need to witness and record these test outcomes accurately.

8. Diagnostic Monitoring

For a 2-3 week period, the commissioning professional will monitor post-testing and diagnostic tests to ensure that all systems perform under natural occupancy.

9. Operations Manuals and Training.

The contractors provide operation and maintenance manuals and are then used to train the building personnel and occupants if necessary.

10. Warranty or Post-Construction

The building’s mechanical systems may experience inconsistency in performance during different seasons. Hence, they may be required additional testing during peak cooling and heating seasons. If any issues arise, the general contractor’s post-construction team will troubleshoot during the said warranty period.

11. Final Commissioning Report.

Last but not least, the final commissioning report will summarize all findings, completed tasks and include any relevant documentation from the commissioning process.

Conclusion

The main objective of the commissioning process in a building project is to ensure that all building systems perform at their peak, according to their design requirement and the building owner’s expectations. Laying out a project’s plan is crucial to help make for a seamless construction process, from start to finish.

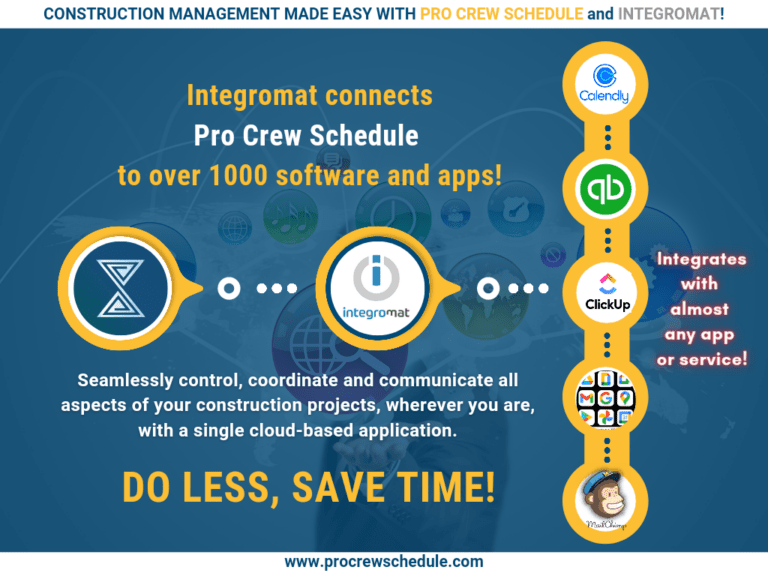

Streamline the commissioning process of your projects by implementing construction management software to make sure that you are right on schedule, with tasks delegated realistically that you can also monitor as you please. Start your 30-days free trial with Pro Crew Schedule today.