The increasing utilization of sprayed concrete in the construction industry is one of the primary growth factors in the market. Sprayed concrete is becoming increasingly popular among builders and contractors, as its application is highly flexible and economical. The global market for sprayed concrete is projected to rise at an annual growth of more than 8% by this year, 2021.

You may already have heard sprayed concrete before, but have you wondered what it is? This blog will discuss what sprayed concrete is, including its properties, types, many benefits, and various applications.

What is Sprayed Concrete?

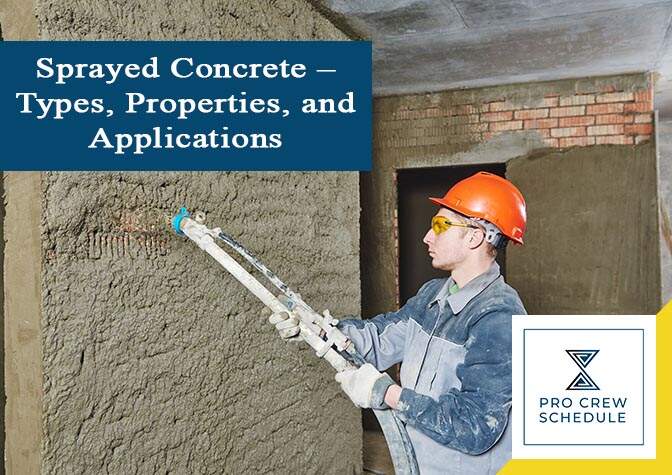

The term “sprayed concrete” commonly refers to simply applying concrete using compressed and pressurized air. The resulting structure is typically self-supporting and doesn’t entirely rely on formwork. It is a method by which concrete is being sprayed into a particular place, rather than the more traditionally used concrete pouring.

High-quality and durable sprayed concrete has become a critical component of stabilization and ground support in tunneling and other projects. Also, one of the reasons why sprayed concrete becomes a popular trend in the industry is due to its many advantages, such as below:

- Compacted, consolidated and placed at the same time.

- Adheres to surface better than typical concrete

- It has a maximum aggregate size of three by eight inches that can help in improving manageability and quality.

- It can be mixed with steel fiber in replaced for welded wire mesh, delivering a much better flexural strength, toughness, and ductility.

- Lower permeability and reduced shrinkage

- Generally less expensive compare to conventional concrete

Properties of Sprayed Concrete

When compared to poured concrete, the sprayed concrete usually obtains more certain properties, making it superior and unique. The properties acquired uniquely are due to various methods employed directly for mixing, placing, and transporting rather than the component materials used.

Listed and explained below are the properties of sprayed concrete:

- Water-cement ratio – the sprayed concrete typically possesses a water-cement ratio that is usually lesser than the conventional poured concrete. This particular condition is observed more during the drying process, where the lower water-cement ratio usually avoids sagging. In the instances of a wet process, the lower value of the water of a cement ratio is gained with the help of a plasticizer.

- Density and permeability – as mentioned already, compaction of the mix is being employed by the high-velocity application. This particular compaction will make the mixture much denser and free from voids. It will decrease the permeability of the sprayed concrete structure.

- Strength of the sprayed concrete – it is viewed that the sprayed concrete can obtain higher compressive strength during the early stage by deploying a lower water-cement ratio. The compaction of the sprayed concrete will then be carried out by spraying at a high velocity. Therefore, the compaction tends to increase the strength.

- Adhesion and bond strength – the sprayed concrete facilitates surface tension and good bonding with the substrate. This particular property of sprayed concrete can reduce the use of coatings or bonding agents, except in certain conditions.

- Thickness of sprayed concrete – the fluidity of sprayed concrete can make them sprayed in a much higher volume and speed. The retaining wall or tunnel wall lining can be instantly sprayed with the lining mass after excavation. The application of sprayed concrete in various thicknesses can help in the deduction of thermal stresses in construction.

- Freeze and thaw resistance – the problem of freezing and thawing often exists with the increase of permeability. In the case of sprayed concrete, there’s a higher impermeability property that can make them resistant to freezing and thawing issues. It will help in the reduction of propagation and crack formation. In terms of abrasion, the resistance is expected to increase due to its watertight property.

Types of Sprayed Concrete

The two trade terms for sprayed concrete are gunite and shotcrete. While shotcrete and gunite are essentially the same materials, however, they are applied with different processes. Shotcrete is the common term for wet process sprayed concrete, while gunite is the popular term for dry process sprayed concrete. The two processes of sprayed concrete mix is a designation for how it’s going to be installed.

Dry Process of Sprayed Concrete Mix

If you’re going to choose this process, a predetermined amount of cement and aggregates should be mixed in the correct ratios. There must no water to be placed in the case of the dry process. Using a purpose-designated machine, the mixture should be fed and taken at a higher velocity air-stream. Doing so will make the mix be carried by the hose of the spraying nozzle.

The dry process uses the norm that the cement/aggregate ratio of the mix at an ideal amount can facilitate workability and good transportation capability. Also, the slump aspect isn’t taken as a criterion in this process. Therefore, for overhead construction and limited thickness, the dry process works best in your projects.

Consider using construction management software for builders and contractors in any of your projects. There are clear advantages when adopting and using construction software. Your overall project management, inventory, crew management, and scheduling can be dramatically improved using this specialized software.

Don’t get left behind and request a live demo now! Click here.

Advantages of Dry process:

- The holding time is unlimited

- There’s no concrete waste generation

- Early strength is higher, facilitating stabilization and sealing works at the initial stages.

Wet Process of Sprayed Concrete Mix

The wet process of sprayed concrete makes use of the mixture containing aggregates, cement and weighed volume of water for the entire mix. In this process, make sure to make the whole mixture even before the pumping process is carried out. To bring the entire mix into the correct position, you should employ high-velocity air. Then, the high-pressure air and the nozzle with resultant velocity will be responsible for spraying the concrete to the areas where it should be applied.

When choosing this process, maintain a proper balance between the fine and courage aggregates to obtain optimum performance. Use construction software for small builders to seamlessly track the whole process, from start to finish. Monitoring crew members involved in such procedures become easier too when you use this specialized software tool.

Advantages of Wet Process:

- The level is reduced and rebound to a factor of two or four.

- There’s less dust generation. Thus, the working environment is being improved.

- High-quality sprayed concrete.

- Spraying with less air demand.

Many Applications of Sprayed Concrete

In construction, the use of sprayed concrete is increasing on a daily basis. While many tech trends are emerging in the industry, especially for project management for construction, inventory, and project scheduling, sprayed concrete is becoming popular among contractors and builders because of its many benefits.

So, other than using the conventional concrete method, you can try and start exploring sprayed concrete. In fact, there’s a wide variety of construction projects where you can utilize sprayed-on concrete. See below:

- Restoration of historic buildings

- Trenching stabilization

- Concrete repairs

- Sealing works

- Excavation stabilization

- Slope Stabilization

- Tunnel Underground Construction

- Tunnel and underground chamber lining

Some General Application Tips You Can Follow

Sprayed concrete can only be done and installed by trained operators. Sprayed concrete usually requires more experience and expertise because the operator is obligated to make adjustments to the water content for the entire application process for optimal results. Any possible errors may ruin the finished product, which isn’t the goal in the first place. For that reason, it’s an important consideration to use subcontractor scheduling software. Taking full control of the application process, tracking and monitoring will become easier, resulting in minimal mistakes.

Moreover, here are some applications tips that may help you and your team when choosing sprayed concrete:

- Concrete joints have to be designed as if you’re placing regular concrete.

- Sprayed concrete should be cured similarly to poured concrete. In fact, moist curing is the ideal method, but curing can be done with membrane curing compounds.

- Shotcrete can be used to fix existing concrete even without the need to have a bonding agent being applied to the repaired surface.

- Sprayed concrete must be well-protected with a surface sealer. It should also be maintained by eradicating any materials that may lead to surface deterioration.

- Success depends primarily on the actions and skill of the nozzle operators. The nozzle must be ACI-certified for this certain application.

- Sprayed concrete can utilize the same steel reinforcement as precast or poured concrete.

- There are various textures that can be applied to the sprayed concrete’s finished surface.

- Gunite and shotcrete have the same fire rating as typical concrete

- Sprayed concrete should be well-protected from the rain until it obtains its final set, typically between 4 to 5 hours. And following the final set, it must be wet-cured for 4 to 7 days.

- Shotcrete can be used to fix existing concrete without you needing to have a bonding agent to the surface being repaired.

- After 28 days of drying, typical shrinkage ranges from 0.06 to 0.10%. The percentage is usually higher compare to poured concrete with similar strength.

- Lastly, the success of the entire application of sprayed concrete cannot be achieved if you don’t use construction scheduling software. Level up your tracking, monitoring, and scheduling using this state-of-the-art technology to deliver high-quality output in any of your projects.

Key Takeaways

The acceptance and application of sprayed concrete are now worldwide. The processes of this method allow complex structures and shapes to be formed without the higher costs associated with formwork. On top of that, with sprayed concrete, builders, contractors, and designers can now have the freedom to achieve almost any shape.